Fully automatic making bags, from Roller Materials feeding, Color code Deviation, welding, pulling, Wastage collecting, cutting

PLC+HMI control, Servo-motor pulling optional, Deviation sensor control the posation

Peeling bag edges or cutting edges optional

Air shaft fix the rolling materials

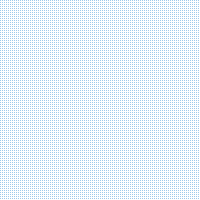

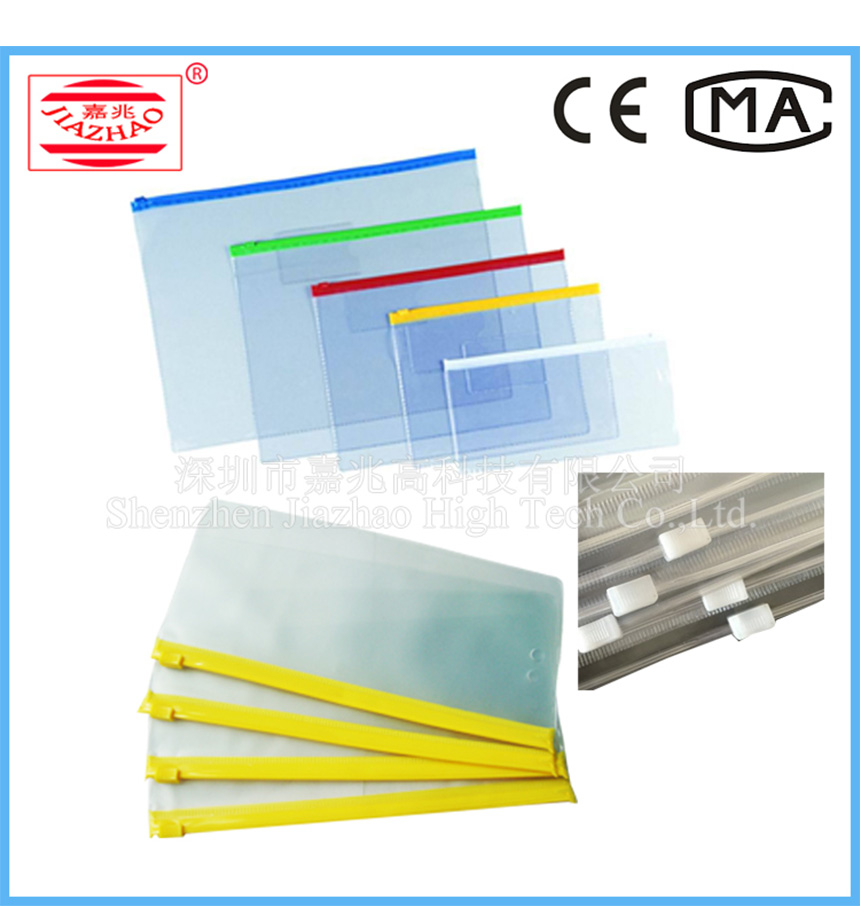

Mainly for makes PVC,TPU,EVA bags , ID bags, Stationery bags, flat bags, Medical bags like Urine bag, Drainage bags, Blood bags, Name card bags, A4 bags, Clothes bags etc.

Fully automatic making bags, from Roller Materials feeding, Color code Deviation, welding, pulling, Wastage collecting, cutting

PLC+HMI control, Servo-motor pulling optional, Deviation sensor control the posation

Peeling bag edges or cutting edges optional

Air shaft fix the rolling materials

| Voltage | 380V 3P4W |

| Power | 10KW |

| Frequency | 27.12MHz |

| Temperature Auxiliary | 0~200℃ |

| Control | Pneumatic |

| Vibrational tube | E3069 |

| Upper plate size | 600x800mm |

| Stroke | 150mm |

| Down Plate size | 750x850mm |

| Input power | 15KVA |

| Belt Width | 640mm |

| Conveyor Step | 800mm(Adjustable) |

| Anti-Spart system | |

| Speed | 15~20 pcs per minute |

| Automatic roller materials feeding system | |

| Automatic roller materials pulling system | |

| Suitable PVC thickness | 0.1~0.5mm |

| Air Pressure | 0.3~0.7Mpa |

| Pressure adjustable by regulator | |

| Tension Distribution system | |

| Down time, weld time, Cooling time,lift time Separately controlled | |

| Manual mold and Automatic mode Switch | |

| Production counter | |

| Ampere Meter check the Power | |

| Power adjust by Shaft handle | |

| Welding time | 0~10s adjustable |

| Machine Size | 665*170*180cm |

| Machine Weight | 2100kg |

+86-752-2222316

+86-752-2222316

No. 9, Dongsheng Middle Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou (Factory Building No. 12), China

No. 9, Dongsheng Middle Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou (Factory Building No. 12), China

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.