A set of XINJE PLC

One XINJE touch screen

One set of main control electric cabinet and operable monitoring electric box (self-made)

WINPARK digital display temperature controller one set

One self-made rack

Three sets of Taiwan AIRTAC cylinders

Hot plate welding machine (English note: Hot plate welding machine) uses the principle of electrothermal melting to control temperature changes, and is equipped with perfect mechanical devices to achieve perfect welding, making up for the shortcomings of ultrasonic welding machines for welding large and special plastic workpieces. It is mainly suitable for welding thermoplastic materials such as PP and PE, and plastic workpieces with large and complex welding joints. For example: automotive water tanks, fuel tanks, carbon tanks, brake fluid tanks, bumpers, instrument panels, exhaust gas purifiers, batteries, motorcycle asphalters, plastic balance rings for washing machines, plastic doors and windows in construction industries, plastic joints, PP Toilet lid welding machine, PP pallet welding machine, PP plastic pallet welding machine, PP plastic pallet welding equipment, pallet hot plate welding machine, horizontal hot melt.

1. Electronic control part

* A set of XINJE PLC

* One XINJE touch screen

* One set of main control electric cabinet and operable monitoring electric box (self-made)

* WINPARK digital display temperature controller one set

* One self-made rack

* Three sets of Taiwan AIRTAC cylinders

* Five sets of Taiwan AIRTAC solenoid valve

* Several customized heating tubes

* Ten sets of customized lengthened linear bearings and bearing steel guide rods

* Four sets of "Peace" button switches

* Four sets of Yixin vacuum generators

2. Mechanical part

* Rack

The frame is welded with domestic high-quality A3 square pass and channel steel. The sealing plate is processed and formed by a CNC bending machine and a punching machine. The whole machine has a strong sense of three-dimensionality, beautiful appearance and durability.

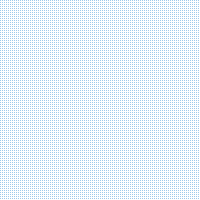

* Hot plate moving mechanism

The hot plate moving mechanism is composed of air cylinder, precision bearing optical axis, propulsion plate and other components. The pneumatic cylinder is used as the power source to drive the hot plate mechanism to move forward and backward along the two bearing optical axes.

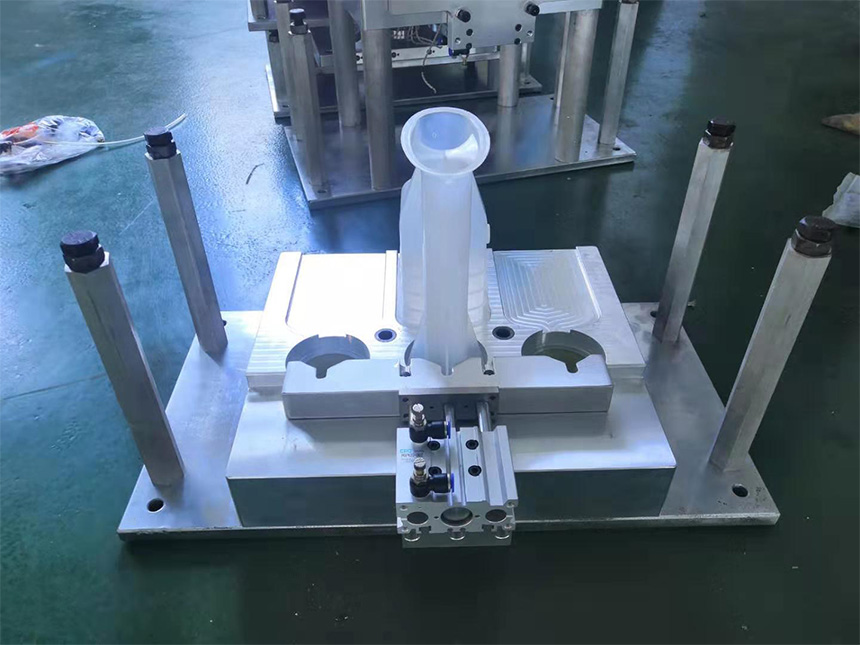

Hot plate component: It is composed of hot mold and heating plate. The hot mold and the heating plate are connected with the hot plate moving mechanism through a fast positioning and fastening mechanism. The most advanced production technology is used for processing, and the CNC "machining center" combines fine hand-made to ensure processing accuracy.

Structural characteristics: When the hot plate is in motion, it is stable and the movement gap is small. On the hot plate mechanism, there is a quick connection mechanism with a heating plate, upper and lower hot molds, and a heating plate fixed hot mold, which can effectively and quickly replace different products, optimize the mold change process, and improve production efficiency.

* Upper and lower cold formwork moving mechanism

The upper and lower cold templates are respectively connected with the template by four guide rods to form the main moving parts of a device.

Upper template moving mechanism:

The upper template moving mechanism is composed of air cylinders, linear bearings, four guide rods, molds, mold pneumatic clamping devices, vacuum suction cups and other components. The air cylinder acts as a power source to drive the template mechanism to move linearly up and down along the four shafts. The vacuum system uses a vacuum generator to output the vacuum pressure, and the plastic parts are firmly sucked through the vacuum suction cup to ensure the correct positioning of the plastic parts and not damage the surface of the plastic parts.

* Mould material: aluminum and steel

| Machine size | (L)1300×(W)1100×(H)1700(MM) |

| Source Supply | 380VAC 50/60HZ 3P5W |

| Heating Power | 1-3KW |

| Consumming Power | 1-3KW |

| Hot plate stroke | 0-300mm |

| Up and down plate Stroke | 0-400mm |

| Air Supply | ≥4M3/MIN |

| Air Pressure | 0.3—0.6MPa |

| Plastic welding Max size | 250mm×300mm |

| Machine weight | 350KG |

+86-752-2222316

+86-752-2222316

No. 9, Dongsheng Middle Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou (Factory Building No. 12), China

No. 9, Dongsheng Middle Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou (Factory Building No. 12), China

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.