Time:2024-06-20 Views:1 source:News

Embossing technology is a commonly used decorative method in textile and leather processing, which can add unique textures and patterns to products. As a embossing machine manufacturer, we deeply understand that improving the quality of embossing is crucial for our customers. In this article, we will share some tips and methods to improve the quality of embossing, helping you better utilize the embossing machine and achieve better results.

Firstly, selecting the appropriate embossing machine is crucial. Different embossing machines may have different characteristics and functions, so it is important to carefully consider your needs and budget before purchasing. A good embossing machine should have stable working performance, adjustable pressure and temperature control system, and easy operation and maintenance.

Secondly, the correct selection of embossing molds is also the key to improving the quality of embossing. The selection of molds should be based on the material and design requirements of the product, ensuring that the texture of the mold is clear, durable, and matches the product. In addition, regular cleaning and maintenance of the mold are also important steps to maintain the quality of embossing, in order to prevent impurities and dirt from affecting the mold.

It is also important to ensure that the material and surface treatment of the product are appropriate before embossing. Different textiles and leather may require different processing methods to ensure consistent and long-lasting embossing effects. Before embossing, professional washing and ironing methods can be used to prepare the product to ensure better results.

In addition, controlling the pressure and temperature of embossing reasonably is also the key to improving the quality of embossing. Excessive or insufficient pressure and temperature can have a negative impact on the quality of the product. Therefore, it is very important to adjust the parameters of the embossing machine according to different materials and design requirements. Before starting embossing, some experiments and sample production can be carried out to ensure good results are achieved.

Finally, regular maintenance and upkeep of the embossing machine is the key to ensuring the long-term stability of embossing quality. Cleaning and lubricating key components of the machine, regularly replacing worn parts, and regularly calibrating and adjusting the machine can effectively extend the service life of the machine and maintain good embossing effect.

Read recommendations:

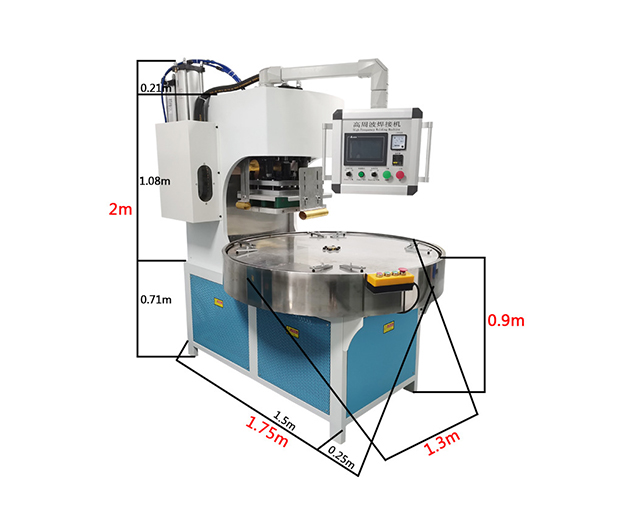

Automatic Rotary High Frequency PVC package Welding Machine Precision Disc

hf High Frequency Automatic PVC Welding Machine Double Sided Blister Packaging for Plastic Materials

Automatic disc high frequency welding and cutting machine

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.