Time:2025-01-11 Views:1 source:News

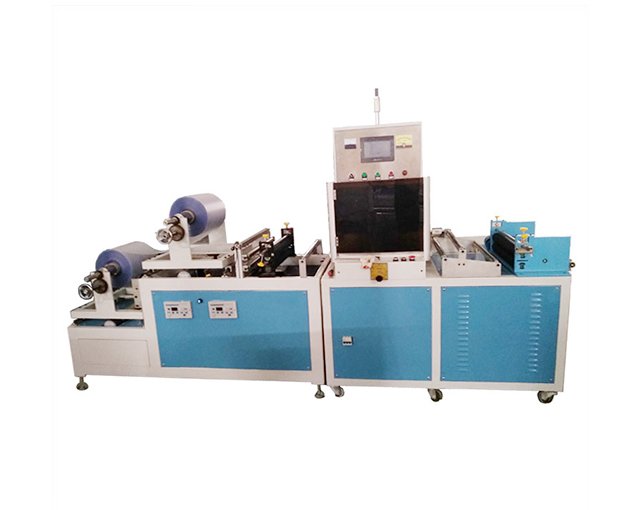

Roller embossing machines offer several distinct performance characteristics that make them valuable in various industries.

One of the key features is their ability to create highly detailed and consistent embossed patterns. The precision-engineered rollers ensure that each impression is uniform, resulting in a professional and aesthetically pleasing finish. This is particularly important in applications where product appearance is crucial, such as packaging, textiles, and leather goods.

Another notable characteristic is the versatility of roller embossing machines. They can work with a wide range of materials, including paper, plastic, fabric, and metal foils. This allows for a diverse range of applications and enables manufacturers to meet the specific needs of different customers and markets.

Speed and efficiency are also important performance aspects. Roller embossing machines can operate at high speeds, enabling large-scale production runs. The continuous process of passing the material through the rollers allows for quick and efficient embossing, reducing production time and increasing productivity.

In addition, these machines often offer adjustable settings for pressure, temperature, and speed. This allows operators to fine-tune the embossing process according to the specific requirements of the material and the desired embossing effect. This flexibility makes it possible to achieve different levels of embossing depth and clarity.

Furthermore, roller embossing machines are generally reliable and durable. They are designed to withstand the rigors of continuous operation and are built with quality materials and components. This ensures long-term performance and reduces the need for frequent maintenance and repairs.

Overall, the performance characteristics of roller embossing machines make them a valuable tool for adding decorative elements and enhancing the visual appeal of various products. Their precision, versatility, speed, adjustability, and durability make them an essential part of many manufacturing processes.

Read recommendations:

jeans metal plastic button punching machine

Pneumatic foot HF plastic welding machine

Double Head Pedal high frequency Wedling and Cutting Machine Foot-operated HF Passport Making

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.