Industrial special embossing machine Industrial embossing machines play an important role in modern industrial production. Industrial embossing machines typically have powerful performance and high production efficiency to meet the needs of large-scal

Process of PU embossing machine PU embossing machine is mainly used to create various exquisite patterns on PU materials. The operation process includes the following main steps. Firstly, the preparation work. Check whether the various components of t

The multifunctional embossing machine is a versatile device that provides efficient processing solutions for many industries. In the textile industry, multifunctional embossing machines can be used for embossing various fabrics. It can press exquisit

As an important mechanical equipment, embossing machine can extend its service life and ensure stable production through good maintenance. The following is a detailed embossing machine maintenance process. Firstly, a comprehensive inspection of the e

Ultrasonic plastic welding machine is an efficient and environmentally friendly plastic welding equipment that utilizes the high-frequency vibration energy of ultrasonic waves to generate high temperatures on the contact surface of plastic parts in a

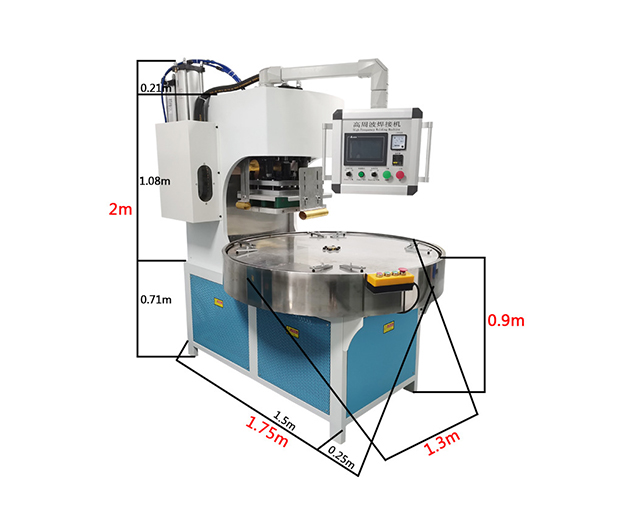

Leather flat embossing machine is a specialized equipment used for leather embossing. It usually consists of a frame, heating system, embossing mold, and control system. When working, first place the leather material that needs to be embossed on a fl

Aluminum foil embossed wire is a product with unique charm and wide application prospects. It not only increases the decorative value of aluminum foil but also enhances its functionality by pressing various exquisite patterns on the surface of the foi

Hot press embossing machine equipment is a widely used device in the field of material processing. From the perspective of working principle, it mainly utilizes thermal energy and pressure to achieve embossing treatment of materials. Equipment is usu

Steel plate and stainless steel plate embossing machine Steel plate and stainless steel plate embossing machines play a crucial role in the field of metal processing. Structurally speaking, this embossing machine usually has a sturdy body frame to wit

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.