Embossing machine transportation logistics refers to the specialized planning, packaging, and shipping processes designed to safely deliver embossing machines—heavy-duty equipment used in industries like printing, packaging, textile, and leather processin

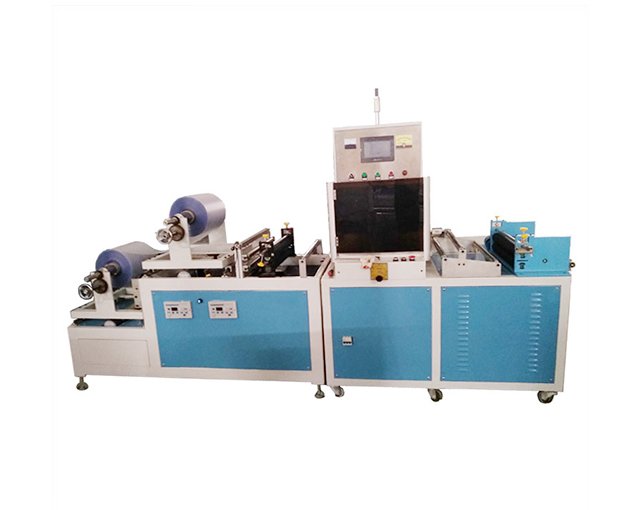

The design of an embossing machine production line is a systematic project that integrates process optimization, equipment layout, and workflow efficiency, aiming to meet the production needs of different materials (such as metal sheets, plastic films, an

The Embossing Machine is a versatile industrial device that creates raised or recessed patterns, textures, or designs on various materials by applying heat and pressure—transforming plain surfaces into visually appealing, tactile products. Its application

CE certification is a mandatory requirement for embossing machines sold within the European Economic Area (EEA), indicating compliance with strict health, safety, and environmental protection standards. This certification allows manufacturers to freely ma

The Embossing Machine Accessories Replacement is a critical maintenance procedure to ensure the machine maintains optimal performance, consistent pattern quality, and safe operation. Embossing machines rely on several key accessories—pattern plates (dies)

Plastic materials used in embossing machines are carefully selected to ensure they can withstand the heat, pressure, and mechanical stress of the embossing process while achieving precise and consistent decorative patterns. These materials play a critical

Rollers are the core components of embossing machines, responsible for applying pressure and transferring patterns onto materials such as paper, fabric, leather, plastic, and metal. The selection of roller materials directly impacts the embossing quality,

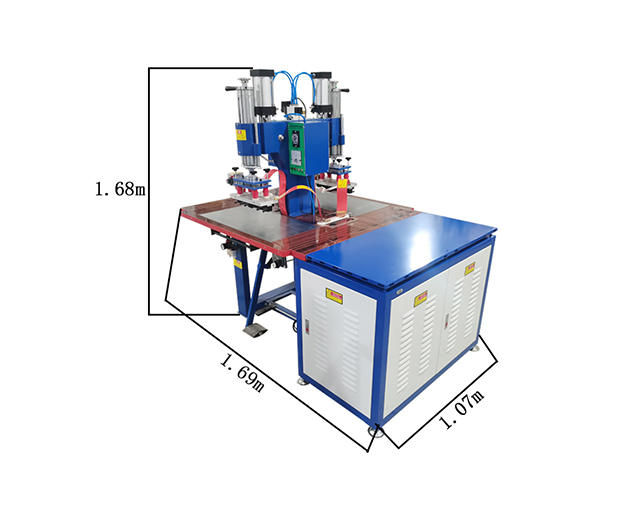

When comparing embossing machines, technical parameters are crucial in determining the most suitable device for a particular application. These parameters can vary significantly depending on the type of embossing machine, its intended use, and the industr

Green manufacturing of embossing machines refers to the design, production, and assembly processes that minimize environmental impact, reduce resource consumption, and prioritize sustainability—from raw material selection to end-of-life disposal. This app

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.