Roller embossing machines offer several distinct performance characteristics that make them valuable in various industries. One of the key features is their ability to create highly detailed and consistent embossed patterns. The precision-engineered

Regular maintenance is essential to ensure the optimal performance and longevity of roller embossing machines. Firstly, daily inspection should be carried out to check for any loose bolts, nuts, or fittings. This includes examining the mounting of the

A high-precision ultrasonic embossing machine is a state-of-the-art piece of equipment that offers exceptional performance in the field of fabric and material embossing. This machine is designed to create intricate and detailed patterns with utmost pr

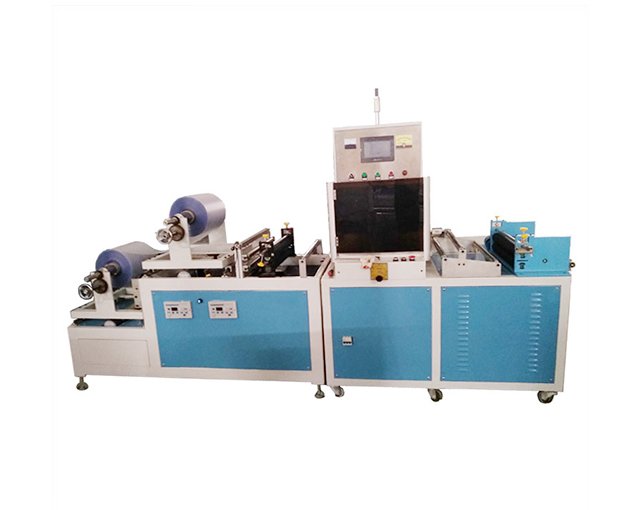

A high-efficiency ultrasonic embossing machine is a game-changer in the world of material processing. This advanced piece of equipment is designed to deliver outstanding results in a short amount of time, making it an ideal choice for businesses looki

The high-speed and high-efficiency ultrasonic embossing machine is a powerful tool for industries that require rapid production and high-quality embossing. This machine is designed to meet the demands of modern manufacturing by offering exceptional sp

The industrial-grade ultrasonic embossing machine is a heavy-duty and robust piece of equipment designed for demanding industrial applications. This machine is built to withstand continuous use and harsh working conditions, ensuring long-term reliabil

Proper maintenance and repair of roller embossing machines are essential to ensure their long-term performance and the quality of the embossed products. Regular maintenance starts with cleaning the rollers. Over time, debris, dust, and remnants of the

Small ultrasonic embossing machines have become increasingly popular in various industries, especially in the production of small-scale and detailed embossed products. These machines are designed with compactness in mind, making them suitable for work

The multifunctional plate embossing machine is a versatile piece of equipment that offers a wide range of functions to meet various industrial needs. One of the main functions of the multifunctional plate embossing machine is its ability to create di

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.