1. The embossing equipment first connects to the three-phase power main switch, and then turns on the power switch on the machine side control box. If there is a high cycle switch, do not turn it on temporarily, and then turn on the electric heating p

The CNC lathe processing technology utilizes the automatic rotation motion of the product workpiece and the linear and curved motion of the tool on the lathe to change the shape and shape of the billet. Specification, production and processing to meet

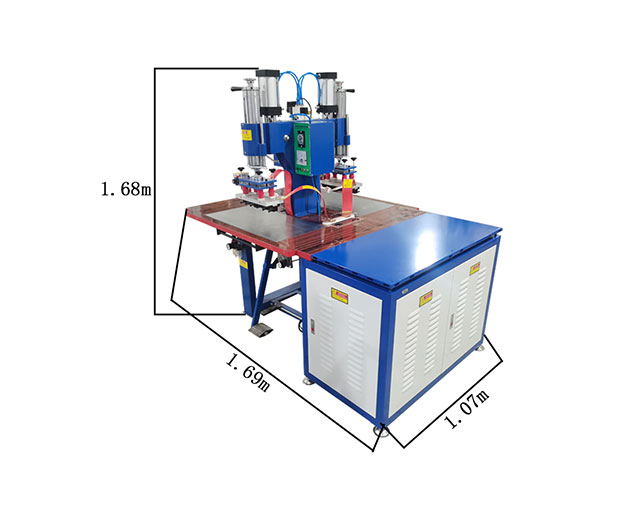

1、 High frequency clothing embossing machine is designed for a wide variety of clothing, including T-shirt cedar, wool cedar, cotton fabric, polyester, denim, various leather materials, and leather product embossing. The general embossing time is fast

CNC machining is a multidisciplinary and comprehensive high-tech that integrates computer, automatic control, modern measurement, microelectronic control, and information processing. It has achieved rapid development and great popularity in the field

Convenient installation Lightweight and compact, with a weight of only 3.6 kilograms per square meter, it is easy to handle and install, and is not limited by seasonal climate and geographical environment. This not only accelerates the project progre

With the continuous updating of trends, design concepts are also emerging one after another, with each wave following the other. In terms of craftsmanship, it also closely follows the pace of design, presenting the concept of one piece design at the f

As the name suggests, a leather embossing machine is a machine that processes leather. So, what are the steps for processing leather? The main steps include tanning, dyeing, classification, polishing, decoration, and topcoat protection. After these st

Embossing machine is a machine and equipment used to improve the glossiness of paper. The safety precautions for the calendering inlet of the embossing machine during operation are as follows: At this point, when the paper is guided, it is automatica

1、 By purpose Leather for daily use, national defense, industry and agriculture, and cultural and sports goods; 2、 According to the tanning method Chrome tanned leather, vegetable tanned leather, oil tanned leather, aldehyde tanned leather, and com

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.