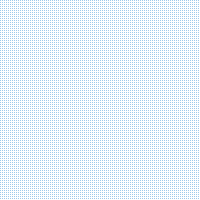

The whole machine consists of pulley, reed seat, tongue block and main shaft to form the power transmission mechanism.

The stamping mechanism is composed of crank, connecting rod, straight shaft, upper and lower dies.

The starting control mechanism is composed of bumper, gate and pull rod.

The belt wheel set is idle on the upper shaft, and the tongue block seat is fixed on the upper shaft.

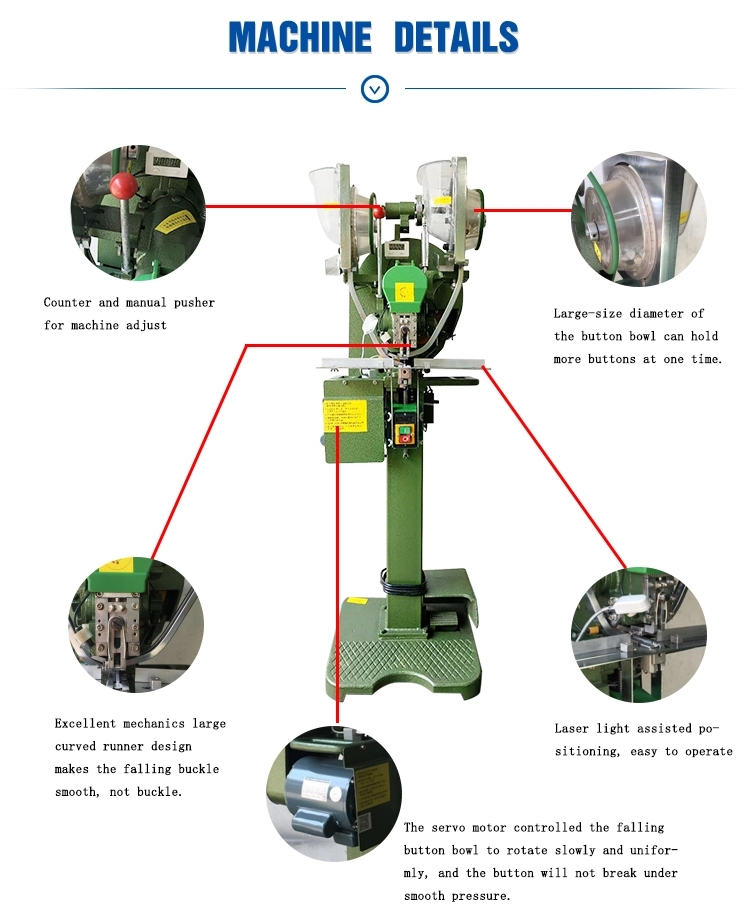

For Plastics and metal Prong buttons, Snap buttons attaching on the fabrics , clothes, Plastic bags.

Applicable to all kinds of clothing, knitted garments, down jackets, denim clothing, shoes and hats and leather, plastic, canvas products, various metal snap buttons, craft buckles, denim buttons and rivets, springs, snap buttons, shoe rivets, etc. . For various buttons and different thicknesses of clothing and wrapping materials, you only need to adjust the mold and slightly adjust the stroke to obtain the quality standard of binding you require. In addition, double insurance safety devices are adopted, which are convenient to use and maintain, and have stable performance. Various special molds can be configured according to customer requirements.

The whole machine consists of pulley, reed seat, tongue block and main shaft to form the power transmission mechanism.

The stamping mechanism is composed of crank, connecting rod, straight shaft, upper and lower dies.

The starting control mechanism is composed of bumper, gate and pull rod.

The belt wheel set is idle on the upper shaft, and the tongue block seat is fixed on the upper shaft. The tongue block is installed in the tongue block seat, and is left and right by the gate plate and the top spring. When the gate plate is pulled down by the pedal, the gate plate will be released. Tongue piece, when the tongue piece collides with the pulley, the main shaft is driven to rotate by the pulley, and the straight shaft runs up and down through the slider crank mechanism. The upper die installed at the lower end of the straight shaft is punched up and down along with the straight shaft, and cooperates with the lower die installed on the machine base to punch the metal buckle and fix it on the fabric.

| Power Source | Electricity |

| Voltage | 220V 1 Phase |

| Power | 200W |

| Gross Weight | 130KG |

| Dimension | 385*465*1080mm |

| Button diameter | 6-17mm |

| Button length | 3-12mm |

| Speed | 1410 r.p.m |

| Horsepower | 1/3HP |

| Power consumption | 0.18KW /hour |

| Throat deepth | 65mm |

| Rivet height | 23mm |

Machine detail and Samples

+86-752-2222316

+86-752-2222316

No. 9, Dongsheng Middle Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou (Factory Building No. 12), China

No. 9, Dongsheng Middle Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou (Factory Building No. 12), China

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.